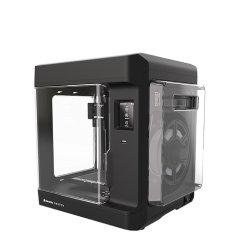

Tackle huge jobs with confidence and maximize uptime of your UltiMaker S5 and S7 with automatic material reloading.

For power users who utilize every square millimeter of the UltiMaker S5 and UltiMaker S7's huge build volume, a single spool of filament isn't always enough to supply an entire print, and you rarely start out with a full spool loaded. The UltiMaker S5 / S7 Material Handling Station holds up to six spools of material and will automatically detect any UltiMaker materials via their NFC identifiers. When the Blue CPE in bay 1 runs out, the Material Handling Station will automatically start feeding a new spool of Blue CPE. 3rd party materials are also supported but must be manually identified when loaded. Each bay of the Material Handling Station can supply either the 1st or 2nd extruder, so support materials like PVA and Ionic can also be held at the ready to ensure the success of your next NylonG print. The Material Handling Station uses same-material spools in the order you load them, so be sure to load your half-spools first to use them up!

Always be ready for the next print thanks to automatic material loading with the Material Handling Station.

The UltiMaker S5 and UltiMaker S7 3D printers can create precision, complex parts out of a wide variety of materials from PLA and PETG to glass or carbon-fiber-reinforced nylon. This means that your next 3D print could be wildly different than the current job. With the Material Handling Station's six material bays, your UltiMaker S5 and S7 will automatically unload the materials you are finished with after a print and prepare the new filament so after you clear the build area, the next print gets started right away. By loading your Material Handling Station with various materials and colors, you will be prepared for anything that comes up in your 3D printing workflow. You can be ready for your next print job by pre-loading the next materials even while the UltiMaker is running. The Material Station is able to operate and exchange the currently unused materials while a print is in process.